How to Build a Successful Chemical Storage Process

Chemical storage plays a vital role in keeping workers and equipment safe from contamination. Often the responsibility for planning and executing chemical storage systems falls on facility management. When dealing with heavy, oversized containers or special storage constraints, it is important to choose policies and equipment that help support the day-to-day interactions with these chemicals.

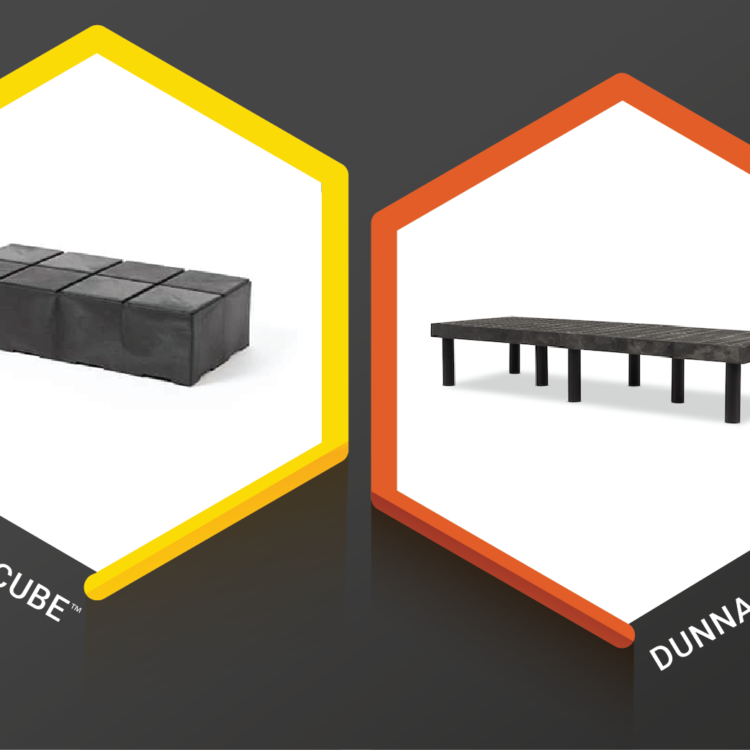

A well-executed plan starts from the ground up. For starters, chemical containers must be stored off the ground and organized. Here are a few reasons why:

- It limits the risk of containers tipping over from foot traffic or uneven surfaces.

- It is more difficult to lift heavy containers off the ground, posing the risk of workplace injury and contamination.

- It is challenging to keep containers organized without a defined space to store them.

Here are some of our favorite chemical storage tips:

1. Choose suitable shelving.

Tailor your investment to the types of chemicals you store. For instance, if you have large, heavy chemical containers, use heavy-duty shelving. Or, if you store toxic hazards and malodorous chemicals, find a solution with ventilated shelves. Audit your current solutions to determine if upgrades are needed.

REMEMBER: Storing large and heavy containers on lower shelves limits the risk of top-heavy units tipping over.

2. Have a secondary containment solution.

It is essential to have a backup plan in every situation, especially with maintaining chemical safety. Secondary containment is not only necessary, but it is an OSHA requirement. Read up to ensure your current procedures are up to date and employees are trained and proficient in secondary containment knowledge.

3. Move containers carefully.

Supply the right tools to limit workplace injury or strain from moving bulky containers. Mobile dunnage options are a great way to efficiently get large or heavy containers across the facility floor while minimizing risks. Consider using at least two workers when transferring chemicals for extra safety.

4. Label your containers.

There should be no room for error in determining which chemical is which—label containers with the name and expiration date to keep track of the lifespan. Organize chemicals by type on the same shelf to limit the risk of potential mix-ups, and post sign-in sheets on each shelf to identify “who” and “when” has used each chemical.

5. What is the environment?

Are there frequent changes in temperature and humidity in the area you are storing the chemicals? Take into consideration the proper environmental factors to limit product loss. If it is an unpredictable environment, it is time to upgrade your space