3 Chemical Containment Strategies for Safety Compliance

Effective strategies can keep your chemical containment protocols up to date and ensure the safety of your employees. But what are some of the issues that professionals face with chemical safety compliance? How do we address this?

Proactive approaches are the best way to limit the risk of chemical exposure. We can do this by creating an internal risk analysis. This process begins with:

1: Identifying potential risk factors.

2: Addressing these risks and finding a solution.

3: Carrying out the solution before interacting with chemicals.

In this article, we’ll help you identify ways our products can support your proactive approaches. Below are some scenarios of what to consider before introducing chemicals in your work environment.

Scenario # 1:

You are about to set up a decontamination station, but there is a lack of organization and there is no strategy outlined to avoid contamination.

The Solution:

Make a plan that outlines the different zones in your facility such as clean areas, decontamination areas, and workstations to set tools or paperwork. Your plan should include emergency protocols for each zone and establish procedures for various personnel. Having plans in place beforehand creates less stress and more focus on the main goal; safety. Have these plans and procedures in plain sight so all individuals feel confident in the process. Support these plans with quality products and equipment that you can count on. Raised flooring should be one of the first considerations. Add-A-Level™ and raised matting will alleviate physical stress and keep workers up and out of harmful substances on the floor surface, while Poly-Riser™ can cover large surface areas by placing panels side by side.

Scenario # 2:

You are looking to establish solutions for clean areas at a decontamination site that makes sanitizing easy while limiting the risk of workers bringing contaminants into the clean area.

The Solution:

While lockers are the go-to solution for use in clean areas to keep personal items safe from contamination, we suggest going one step further and lifting the locker units off the ground. For decontamination sites, lifting locker units off the ground makes it possible to clean all floor surfaces, while easily reducing the chance of contaminating lockers and personal items. Consider Dunnage-Rack™ to do this. This solution is tough, non-corrosive, and chemically resistant.

Scenario # 3:

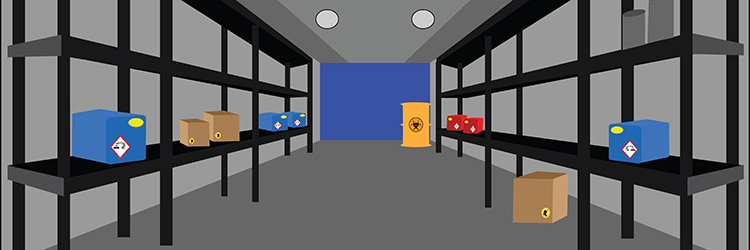

You store large chemical containers in your facility and are looking for a better way to organize barrels. You’re also considering a better shelving solution to withstand potential spills.

The Solution:

Choose a non-corrosive, chemically resistant storage solution such as DuraShelf® or Dunnage-Rack™ to ensure the longevity of your investment. To keep barrels organized, we suggest incorporating Containment Trays to keep different types of chemicals separated and easy to identify with OSHA-certified color coding.

Having a detailed plan and procedure in place before introducing chemicals into the workspace is the key to success. Accomplish your plans and procedures by identifying potential risks and finding effective solutions. Set workers up for success by making this information easy to access and supported by quality equipment. By doing this, you will ensure the safety of individuals and limit the risk of contamination.

To review OSHA’s hazardous materials compliance guidelines, click here!