Responding to Chemical Spills

As a workforce that deals with chemicals, your goal is to prevent spills and properly manage contaminants at all times. However, accidents happen, even with the safest manufacturing processes established. When chemical spills occur, it’s vital that you take immediate action to ensure the safety of everyone involved. Whether the spill is small or large, it can be extremely dangerous to employees working in the facility and any other equipment or products they come into contact with. To prevent workplace injuries due to a spill, it’s best to have a plan in place so workers know how to respond accordingly.

We share five helpful tips to guide you through a spill:

1. Identify the Substance

The first step is identifying what has been spilled, which can be done by looking at inventory lists and MSDSs (material safety data sheets): Your main priority here is to determine whether it could be life-threatening. Some chemicals are only harmful if they come into contact with your skin, whereas others can emit toxic vapors into the air. In each case, you’ll need to handle the spill differently. To make sure everyone knows what chemicals are being used in your facility, print off safety labels for all containers.

2. Protect Yourself and Others

Regardless of how small or large the chemical spill is, it’s essential to protect yourself and others from exposure as soon as possible. To reduce risk, be sure to:

- Wear protective equipment: It’s better to be safe than sorry when it comes to protecting yourself against exposure. If you have access to any kind of respirator or respirator mask (often called “P100s”), you’ll want to use it! This can prevent the inhalation of harmful chemicals in the air around you. If the chemical is safe enough to clean up yourself, be sure also to wear Personal Protective Equipment (PPE), such as a suit, boots, goggles, and gloves.

- Keep people away from the spill area: Especially in the case of life-threatening spills, be sure not to let anyone walk through contaminated sites until they’ve been thoroughly cleaned up; even something as simple as stepping on spilled liquid could cause serious harm.

3. Contain the Spill

Once you’ve determined the spill isn’t life-threatening, the next step is to keep it from spreading. There are a few tools you can use to contain the liquid, which your workspace should already have on hand. These include:

- Sorbent Pads: These are like giant paper towels, but they won’t tear or disintegrate when used. This makes them ideal for spills because they’ll stay put while absorbing liquids, meaning you won’t have to move them around or replace them repeatedly.

- Spill Kits: Limit spill exposure by utilizing an on-site spill kit. Along with sorbent pads, both products can be used to divert the spill for easier cleanup. If appropriately managed, spills can be self-contained using secondary containment such as Containment Trays.

Keep in mind that each spill will require a different strategy to be adequately contained. You might need to create a “dam” for some, while another might need to be diverted by using sorbent materials as barriers.

4. Decontaminate the Area

Once all contaminants have been cleaned and disposed of safely, you’ll need to decontaminate the area—and yourself—as soon as possible. This includes removing all traces of the spill and cleaning up any residue that may have been left behind. If you’re dealing with a corrosive chemical, this will probably mean using a neutralizing agent to prevent further damage.

The best way to decontaminate yourself is by washing your hands with soap and water, as well as thoroughly rinsing any other exposed areas on your body. Don’t forget to discard your used PPE equipment as well!

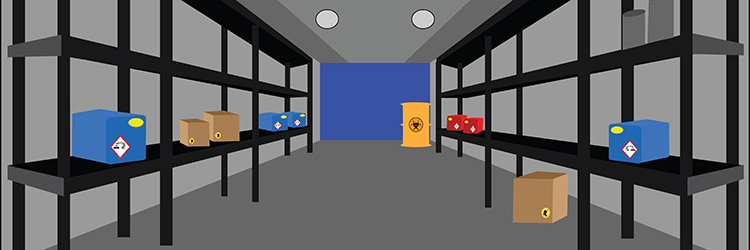

5. Organize Chemicals Effectively

Of course, the best way to deal with disaster is through prevention. Many chemicals can look or even smell the same, and it is dangerous to guess what the contents of a container might be: That’s why OSHA, EPA, and DOT all have requirements regarding labeling containers.

However, it can take time to find what chemical you’re looking for based on a small label on a container—which could be disastrous in the event of a spill. At SPC Industrial™, our containment trays are designed to help you establish a more effective form of labeling, with clearly marked OSHA-certified color codes to keep chemicals organized (and your employees safe).

SPC Industrial™ Safety Solutions

Every workplace should have continuous training put in place and ensure that employees are equipped with the proper knowledge of the chemicals they are working with. Hazardous materials are dangerous to work with, making it essential to have a robust process put in place as a proactive approach to prevent chemical spills. At SPC Industrial, we know the importance of workplace safety. That’s why we offer a variety of safety products so employees can work safely and efficiently.