Chemical Storage 101

If you work with chemicals in your facility, then you understand the importance of planned protocol in regards to the storage and handling of these potentially harmful substances. Let’s take a closer look at what containment is and what it means for your storage.

EPA and OSHA Protocols

The EPA and OSHA both require chemical containment systems. One method includes having a primary and secondary containment for chemicals to ensure there is an extra layer of safety against potential spills. What exactly this method should look like is unclear because no design, device, or product is specified by OSHA or EPA.

Containment Storage Systems

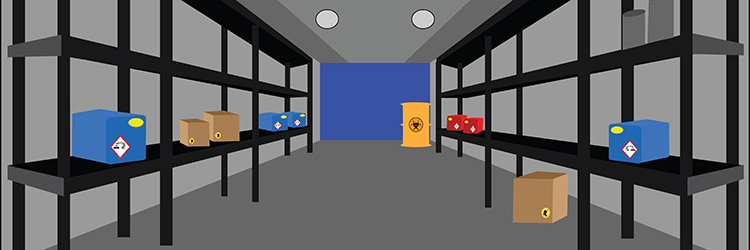

Storage equipment may be easily overlooked, but these behind-the-scenes systems play an important role day-to-day. Choosing reliable storage systems is an important step in safety. Having procedures in place to store chemicals helps prevent product loss, environmental pollution, and work efficiency in your facility.

Lift chemical containers off the ground and out of your walkways by utilizing shelving such as DuraShelf®. Our shelving solutions are chemically resistant and non-corrosive and have many different size options to accommodate large quantities of chemical containers of all sizes.

Organizing Chemicals Effectively

Many chemicals can look or even smell the same, and it is dangerous to guess what the contents of a container might be. That is why OSHA, EPA, and DOT all have requirements labeling containers, however, it can take time to find what chemical you’re looking for based on a small label on a container. Our Containment Trays can establish another form of labeling, clearly marked with OSHA certified color codes to keep chemicals organized and your employees safe.

Get an overview of our Chemical Storage solutions in the infographic below. For more information on DuraShelf’s chemical resistance, click HERE.