4 Strategies for Storing Materials in a Warehouse Facility

Not all storage methods should be treated the same. After all, your storage method should depend on the types of products you need to store. There are many options available when it comes to unit type, and it’s important to consider the pros and cons of each one when it comes to storing your specific products.

Let’s take a look at different types of storage needs and how to best approach them.

Inventory Storage

There are two main priorities to look at when confronting inventory: (1) having ample storage space and (2) making products easy to find and identify. You can accomplish both goals by labeling, combining like products, and using units with multiple shelves. These strategies help make items easily visible so workers can grab what they need at a glance and store items in bulk which improves organization and productivity.

Best units for inventory: Units with multiple shelves for optimal space utilization.

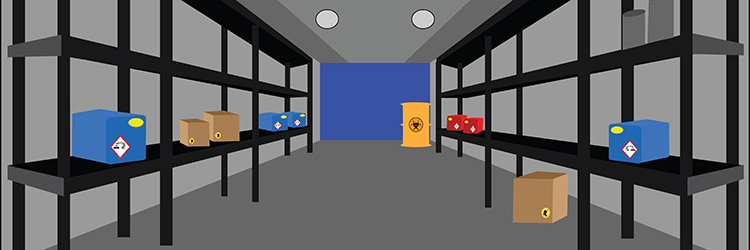

Chemical Storage

Much like inventory, chemical storage should also prioritize identification. Labeling chemicals is not only important for safety purposes, but can help with inventory processes and reduce the risk of using expired products.

To enhance safety protocols, implement a spill containment plan to reduce the risk of chemical exposure with potential spills. Store minimum quantities of chemicals when able to reduce this risk factor as well.

Best units for chemical storage: Non-corrosive shelving that offers enough space between shelves for larger containers.

Heavy Materials

Heavy containers and boxes should always be stored on lower shelves to limit the risk of the unit tipping over. In conjunction with this, store heavier items on the outer parts of the shelves next to leg posts when able, with lighter items placed in the middle of the shelves. This will prevent shelves from bowing under heavier weights.

For long and horizontal items like pipes and lumber, lay items flat across an entire shelf instead of propping them up vertically against walls.

Best units for heavy materials: Units with high weight capacity, made of sturdy material that won’t bend and buckle over time.

Bulk Stacking

Stack like products of the same size and weight when storing bulk items for long periods of time. Secure groupings with shrink wrap or ties to ensure stability, especially when the grouping needs to be moved to different areas. To ensure proper safety, always move bulk stack items with the proper tools, such as forklifts and mobile units.

Best units for bulk stacking: Dunnage or platforms with high weight capacities and easy load and unload accessibility.

At SPC Industrial we pride ourselves in our ability to deliver a storage solution that will help you meet an array of facility storage needs. From chemical storage to heavy materials to inventory management, DuraShelf® is the optimal industrial-grade shelving solution. To learn more about our storage products, check out our products page.